From direct to customer (DTC) brands to Amazon Vendors, manufacturing is driving eCommerce at a double-digit growth rate.

According to a 2020 report, US manufacturers contributed $430 billion in eCommerce sales the previous year — reflecting a 21% sales increase.

How can you use contract manufacturing to launch and grow your physical products business?

You probably want hit products like these winners:

- Pebble Time’s smartwatch

- Peak Design’s Travel Tripod

- Snapmaker 2.0: Modular 3-in-1 3D Printers

- Otto’s G32 modular gas grill

- OYO NOVA Gym

- Bird Buddy’s smart bird feeder

- Whipr’s portable multi-sport training machine

Then you want to pay attention to Jared Haw’s advice. Jared has coordinated manufacturing deals and processes on all continents and across multiple verticals.

Meet Jared Haw and EPower Corp

Jared Haw is the President of EPower Corp, an American and Hong Kong-owned contract manufacturer with self-owned and managed production lines in China.

Jared and his company have developed a team to find solutions to technical and manufacturing issues for companies that are disrupting their industry by launching new products.

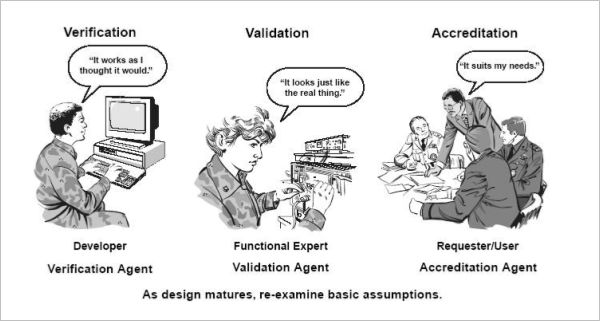

Takeaways from My Interview with Jared Haw

- Market validation is the most important thing about manufacturing eCommerce products that buyers will love

- B2B has to be personable; cold emails won’t work if you’re selling a high-end service (see answer to question 3)

- EPower Corp focuses on helping businesses scale manufacturing for tested products that have never been manufactured in large scale before (see answer to question 2)

- When it comes to product sourcing and manufacturing, Jared says “China is still THE place, 100%” (see answer to question 12)

- Build a product that works first, and your community later. (see answer to question 11)

- You don’t have to out-innovate your competitors, but you should always be developing new products that your market wants. (see answer to question 11)

- Understand how to go to market — great products understand how to go into the market more than their competitors. (see answer to question 11)

- Kickstarter is a form of debt; it’s not the only way to launch a product

My Discussion with Jare Haw

1. Please tell us about yourself and EPower Corp. What experiences or realizations inspired the creation of EPower Corp.

I’m Jared Haw and I’ve been in China since 2012. I graduated from school back in the States. I studied at Beijing University for a short time, and then after that, I decided I wanted to live there.

I lived in Xiamen, which is like an island city off of or across the strait from Taiwan. After that, I was bouncing around from one place to another.

I was doing Schwinn Fitness and Spinning. I was manufacturing those bikes so I was in charge of quality control and assembly.

Image Credit: Schwinn Fitness

That was a pretty large factory with probably 3000 people. So, that was kind of one of my first experiences in manufacturing. And then after that, we were doing Insoles, similar products as well.

It was about four years ago we saw a huge niche and opportunity to provide services to startups and smaller enterprises that are developing unique products. That’s why we started EPower Corp; we saw how the larger manufacturers were working.

I’ve worked with larger factories before, and then I’ve also worked with very small Alibaba kind of companies. So, there was a huge disconnect between the great ones and Alibaba kind of ones.

We wanted to situate ourselves right in between, to provide services for those companies that are developing something unique. They don’t want to just be trading products like when you go to alibaba.com and you type in ‘phone case’ and you buy a phone case from them.

It’s more for people that want to customize their own phone case, or they have some sort of unique product that’s a little bit more on the complex side, maybe anything from 10 parts, 50 parts, a thousand parts. That’s kind of where EPower Corp came from.

2. So, you basically focused on specialty manufacturing, for people who want to manufacture concept products?

Exactly. It was more for the complex side.

If you want to do a phone case or something, there are probably 10,000 factories in China that specialize in making phone cases. But, maybe there’s a different, unique product that no one’s ever made before and there are no case studies on it. No one really knows how to do it, but the manufacturing processes are there. That’s what we are.

Imagine a company like iRobot or vacuum cleaner, they’ve created this product for the first time. So they can’t go work with a large contract manufacturer. They first have to establish themselves.

That’s who we are. They establish themselves with us.

Then, we invest in our production lines. We invest in our labor, skilled, and unskilled because we need everyone to scale up. Everyone should grow together so we could grow with our clients.

3. What challenges did you face building EPower Corp? How were you able to face these challenges and solve them?

The number one thing was definitely trust and credibility. That was by far the most difficult thing, because we were not selling stuff like a razor or a pencil, or cases for AirPods that you could buy for $20.

Some of our clients will spend maybe $100,000 per order, others, maybe $10,000, some will spend $300,000. So, to build their trust was by far the most complicated thing.

Now, it’s a bit easier because we have case studies, we’ve worked with clients, we have referrals, but back when we first wanted to do this, it was like, who are these guys? Like, why are we going to work with them when we can work with this company? So it was very difficult to establish a new sort of trust and credibility.

Our clients will spend… $100,000 per order… $10,000… $300,000. So, to build their trust was by far the most complicated thing

The other one was who we should work with. There’s so many different types of companies out there. Maybe they’re doing apparel, consumer electronics, consumer goods. So, what are we good at? It took some time to figure that out as well.

We were sourcing everything at first, like apparel, consumer electronics, power adapters, water bottles, and all of these things. We wanted to figure out what we were the best at. What is the most amount of fun, what industry, or what area has the most potential for us to go into.

So, it was all these things coming together; to figure out what we’re good at and then to establish trust that, yes, we understand these things, we could make these products for you and we are better than this factory because of X, X, X, X, X.

If you want to build trust, you have to teach someone something that they don’t know.

At first, we did a lot of cold emails, and then we found out that no one wants to transfer production via cold emails.

With B2B, it should be a little bit more personable. It’s not like you’re buying something for $30 — if it’s a crappy product throw it away — who cares?

It was to educate. How would you build trust, in my personal opinion, is through education. If you want to build trust, you have to teach someone something that they don’t know.

So, you have to first realize what they need to know to improve their business. Are they having pricing issues? Are they having quality control issues? You may have 10 different products, and they’re having trouble organizing that through project management, so what is their problem?

If we can solve those problems, we’ve established trust. That means we know what we’re talking about. And we become credible, even if they’ve never heard of us.

That was how we had to face those. We had to work with investors and accelerator programs all around the world.

We’re in, obviously, the US, we’re in Europe, Nigeria, and Australia. We made partnerships with these companies where there were some sort of investors or non-profit organizations that just focused on teaching. And that was it.

We knew we were not going to get any money through these teachings, but we wanted to establish trust, credibility, and that’s how we were able to establish ourselves when we still had nothing.

4. What personal and professional development courses and programs do you invest in and why?

The only thing I care about is education, and if you go to like industrial marketing, there’s not much on it.

If you think of contract manufacturers in the US and anywhere else, they’re dirty; they’re not a good thing. They’re a whole bunch of old people.

Contract manufacturers in the US are usually older generations and they don’t understand how to post a video on YouTube.

So, we’ve had to listen to people like Neil Patel and Gary V, and follow them, because they’re not necessarily for industrial marketing, but they are for each of these sales B2B marketing and establishing relationships.

At the end of the day, we’re no different. Maybe who we’re marketing to would be engineers rather than someone else, but the concepts to do that are going to be relatively the same.

5. Who do you allow into your inbox — whether you’ve bought from them or not — and why?

I use Google for my email. I love Google because it does a really good job of filtering. You have the primary, the social, then the promotion.

So, I will subscribe to someone, maybe even Neil Patel. Then he gives me something that I don’t like, then I put it in promotion and never look at it again.

The only ones that I really do follow would be maybe Angel. They look at investing into new companies because we like to stay relevant. Then there’s Crunchbase, which is looking at private companies that are receiving funds, whether it’s technology, aerospace, or IoT.

We knew we were not going to get any money through these teachings, but we wanted to establish trust, credibility, and that’s how we were able to establish ourselves when we still had nothing.

Mostly, it’s going to be software-based because, obviously, you get your best bang for your buck with software companies, but we like to stay relevant with that.

For marketing, there’s really no one else that we really do follow just because we do have to understand our market and then we act with that.

With marketing, it’s all about acting. If there was someone that did it before us, it’s not going to work for us because it’s not our way. So, we have to understand the marketing of it, and then we adapt it to our market, if that makes sense.

6. In what ways are you helping product makers reduce the risk of manufacturing products that may not gain market traction?

That’s difficult because the most important thing is if the product market fits market validation. If you do not have this, then why sell the product?

Let’s say if you’re selling a case for AirPods for $20 and only 10 people have bought it, it shows that you do not have market validation.

Image Credit: massardo.com

The most important thing is to do our due diligence on the products and the marketing way before the tooling is done. Once we get into tooling, you’ve made that investment. You can invest at 3000 or 10,000. Some of our clients spend $300,000 on tooling.

You better have market validation because we know no one’s going to give you that money back or that time and money that you spend on development.

If there is not that market traction that you thought, you have to rewind, look back, and think why? Is the product aesthetically not good. Does it function well? And then, are there better solutions in the market?

Of course, this should have been all taken care of during market validation when you’re giving prototypes to your users and clicking in their feedback. But, at the end of the day, if there’s no traction, a contract manufacturer like myself is not the solution.

We make products for people that want to buy them. So if you don’t have that market validation, or if you don’t have that market traction, we can’t do too much about it.

We can help you as much as possible in the early stages when you’re collecting feedback. We can walk you through the steps of what to do. We’ve done it so many times.

But, if you don’t have market traction, it’s very difficult to regroup. Sometimes, you do have to cut your losses, unfortunately, and think about the next product. Because, maybe you could learn something about this product and why it failed, and you can build upon that onto your next product.

7. Does your pre-production services include market validation?

No. For us, market validation does not come from us because we do not understand the users. We do not understand the clients.

Let’s say you come to us and say, ‘okay, I want to sell 10,000 of these razors.’ What we’ll do is talk to you about the markets. We want to know who and how the market is.

If you say that the razor business is a $3 billion industry, I’m not sure if it is or isn’t, that means nothing to us. We can say, okay, if I get 1% of that, you’re a millionaire, but you won’t. So, it’s about how are you going to get into the markets?

The worst thing for us is when someone says, yes, we have market validation because it’s a $3 billion industry. When someone says that, we’re done, just because you did not do your research about the actual markets.

The worst thing for us is when someone says, yes, we have market validation because it’s a $3 billion industry.

We will verify that our client’s market validation is correct. Sometimes, they don’t have it completed yet, but we can walk them through it. We could walk them through the prototype process.

For example, to get market validation, you’d probably have to have a prototype. You have to have something made in order to get feedback from the clients. So, we can make the prototype for them.

We could give it to them, and we could talk to them about how they should be distributing this. They should be giving it to investors, community members that are in this industry, or someone that’s going to be providing you with valuable feedback, definitely not your mom or your grandma, because they just don’t want to hurt your feelings.

Then, if the product comes back and they say this product sucks, you didn’t fail. You just have to make corrections to this product to improve it.

But, we can’t do this because we don’t know your clients. You have to be responsible for speaking to your clients, but we will walk you through the steps.

So. I guess in a very unorganized answer, that’s kind of how we look at market validation.

8. Do you help your users with their product launches?

Absolutely. Yeah, we do. But then again, we’re not the key driver. We could provide our opinions. We can say before, we’ve seen this or that to work, and we could help them.

For an example, if a client comes to us and they’re a startup, we ask them about market validation. What are you going to do to launch the product? And they say, Kickstarter, we say, hell no. Kickstarter’s not your only way to launch a product. If that’s your only way to launch a product then you want to fail.

What people don’t understand is that Kickstarter is a form of debt. Whenever someone says that they’ve raised like $30,000 in investment through Kickstarter, they’re just a little naive because people have given you money for a product.

You’ve taken on a form of debts because you have to return that money in X amount of months, days or whatever. And you have to pay them back with products. They paid you early for products.

You have to understand that Kickstarter might be a good platform for your launch, but it’s not THE platform. You have to have some sort of engine behind that as well.

What’s going to happen after Kickstarter? Kickstarter is only 30 days, maybe a 35-day campaign. So then what happens after that? What are you doing in the buildup of Kickstarter as well? Because, if you just launch a product on Kickstarter, who knows about it? You have to build a community.

We want to know your problems and find the solutions for your problems. That’s why we work in this way.

If you’re able to provide us with the feedback of your clients, that’s going to be a very healthy relationship because then we could be the solutions for your clients as well.

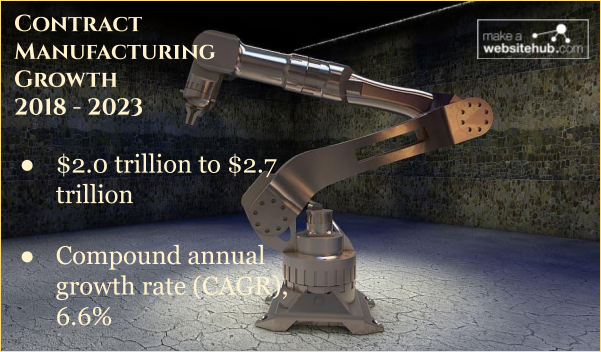

9. According to a report, the global contract manufacturing market should have a compound annual growth rate of 6.6% from 2018 till 2023. Will this drive better product quality and drive manufacturing costs down?

I actually don’t know how to answer this. But let me explain a little. 6% is very small.

If we grow 6% a year, I’ll be very upset.

For us, that would be very sad because we’re very young. We’ve not cashed out. We’re growing.

If we’re doing one year or one quarter, 1000 units, and then a year after that, 6% would be 1060 units. That’s only 60 units more and not enough to get any sort of price reduction.

Even if you look at it in millions; let’s say you have an amazing product, you’re doing a million a year, 6% would be one million sixty thousand. That’s still not enough to get some sort of price break in your product because it’s only 6%. That’s why it’s very hard to answer that question.

But it also depends on what is driving the growth. What kind of materials are driving the growth? With an average of 6%, some are going to be shrinking while some could be growing. Maybe renewable energy will be growing 40% and they’re growing really fast. If it’s growing 40%, you’re going to get some price reductions.

It also depends on how you scale it up. There’s always that worry that if you go from a hundred units to 10,000 units in a matter of a year, you might run into some quality issues.

So, it is very important that the contract manufacturer that you’re working with is able to work with you at very small rates, and they’re also able to scale up with you; they have the infrastructure, production lines, labor, finances to be able to grow up with you.

To answer that, I’m not sure if the prices will decrease, but quality should always be sustained. Quality is built into our products. And that’s what a lot of people don’t know.

Why we’re a little bit more unique is that we can take you from a prototype and we can get you into production with a very good design. We can go through all the stages of developments.

So, if you have quality built into the product, then you will be able to scale up 6%. You’re not going to have any problems.

10. What should a newbie know about hiring contract manufacturers?

A lot of people, when they talk to us, they’re like, you guys are exactly what we need. We’re like, no, we’re not, you need people that want to buy the product. That’s the only thing that matters.

Once you have market validation or once you’re working on it, that’s when we come into play and then we can work our magic.

Once you have market validation or once you’re working on it, that’s when we come into play and then we can work our magic.

So, for a newbie, we’re not the solution if no one wants to buy it. We can make the greatest product in the world, but if no one wants to buy it, we all fail.

Once you have that market fits, people that want to buy it, and once you talk with a contract manufacturer, they could really provide you with a lot of value.

But, you have to understand who and what kind of contract manufacturer you should work with. If you take it to a company like Foxconn, they’re going to say no, because you’re not doing $300 million a quarter. But if you bring this to someone like us, we’re like, okay, that’s a great product. We could see a lot of potential in it.

11. What under-tapped product opportunities are you seeing presently for eCommerce?

Shapewear has a lot of potential, but I don’t do Shapewear. These are just things that, with research, I really think has a lot of potential.

Image Credit: Amazon

Unfortunately, the things I think have potential, we don’t make; things like maybe yoga, which is really growing here even in China. To have a yoga business in China is huge right now. Also, IoT is slowly getting in there, but just because we’re into IoT.

We have to look at products that are really adding a solution to people’s problems. That’s the most important part.

Let’s say if your market is in America, what are the types of products that we should be bringing to the US markets? If your product is in Africa, what kind of products should you be developing to help the African community? These are the products that we touch on and people love because it improves their life.

Once you have that product that people start to take notice of, you can start to build a community. That’s very difficult to do, but some of our clients have done a great job of it. They’ve been able to build a community and they’re like a cult. So, whatever they bring out next, people buy. It doesn’t really matter the product because it’s always a step up from their last generation or the last version.

You don’t really have to out-innovate, but you should always be developing new products that your market wants.

You don’t have to be first to market. I believe that’s a myth.

If you look at a lot of great products out there, they were probably not first to market, and they just understood how to go into the market better than the person that did behind them.

12. Manufacturing in China is becoming tougher. First, labor costs are higher, so manufacturing costs are going up. Secondly, the US-China trade issues. Thirdly, neighbouring Vietnam, and other Southeast Asian countries are becoming attractive. And then, there’s the pandemic.

Here’s my question: What should product developers know about manufacturing in China, the USA, and other countries in Southeast Asia, going forward?

China is still THE place, 100%. These other countries are trying to come out; Vietnam, Thailand, Cambodia, all of these other countries, but they lack infrastructure, size, and labor.

China right now, especially, is definitely lacking labor. It’s very hard for us to find good labor.

I have a friend with a factory in Japan. He hires a majority of his workers from Vietnam. He was saying that in Vietnam, the good workers go to Japan because they get more money. And, the other workers in Vietnam, stay in Vietnam. They are maybe a bit more lazy and they don’t work as hard. They never work overtime. Sometimes they just don’t go to work. You never have these problems in China. So yes, there are definitely some trade-offs.

China has all the materials, even tooling. Let’s say you’re doing a very basic plastic injection molded part. The tools come from China, and then all the resin might be coming from China as well, just because they lack that infrastructure in that home country, whether it be Thailand, Vietnam, or Philippines. Maybe they could do certain parts, but they can’t do complex parts.

If you’re going to some of these other countries, you’re kind of going through the process again. You have to build trust. You have to build the infrastructure.

Labor in China is fantastic. They work six days a week. If they don’t, they quit and then go to another factory. It’s kind of ironic because they complain when they work too hard.

They say, ‘okay, I’m so tired.’ And then you say, ‘okay, fine, you can go home.’ They’re like, ‘well, then I don’t get overtime pay so sorry I have to work.’ That trade-off is a good situation, especially when you’re busy. If you’re not busy, it sucks because you’re going to have to deal with that extra overhead.

China’s future is definitely not manufacturing. China’s future is domestic consumption.

It also depends on the type of product that you’re doing. Let’s say plastic resin or plastic. Plastic resin is a commoditized item. You could buy a plastic resin probably anywhere in the world for the same amount of money.

I believe plastic injection molding in the United States is very competitive compared to China, especially if you have the volume, because you can automate the process. You don’t have to have three Chinese laborers. Maybe you could just have one American.

The cost right there offsets, and then you don’t have to worry about the tariffs. You don’t have to worry about the shipping costs. You can just keep it in the warehouse in the US factory and then ship it wherever.

But let’s say if you’re looking at something with a little bit more assembly. If you’re looking at complex products, those have to stay in China.

That’s why, right now, we’re not really feeling the heat with my factory because we don’t make modernized products. We don’t make things like phone cases, glasses, or anything that is really highly relevant to machines.

We provide a lot of upfront work with the engineering and we have a supply chain based in China that cannot be demonstrated anywhere else. In the US, it’s terrible there, but certainly not in Malaysia or other Southeast Asian countries. That’s why China is growing with the prices, but they do still have the infrastructure. That is if you’re looking at doing a relatively more complex product.

There’s just too many problems as of now to say that China is no longer relevant. Maybe another 20 years, but for now, even with the tariffs, China is more competitive than most countries.

If you’re looking at doing Silicon parts or a plastic injection mold part, maybe you don’t need China. Maybe you could go to another country.

Maybe if you’re from Africa, you could do it locally. If you’re from Europe, maybe you could do it in Poland. If you’re from the US, maybe you could do it in Cleveland. You can look at these options that are more or less available.

China’s future is definitely not manufacturing. China’s future is domestic consumption. They need to first have respect for their own products and buy their own products. My car in China is not a Chinese car; it’s an American car. And a lot of other people have the same mentality.

Chinese people are the worst with it.

If they have a little bit of money, they will never buy a BYD, Geely, or a Chinese brand just because foreign cars are awesome.

What they have to understand is that they have to start to respect their own products. Why buy the Nike that is $120 when you could buy a local brand for $20 that has a similar quality.

So, that’s what they first have to understand; that they could make superior products. We all know this because the knockoffs of Rolex are just as good as a real Rolex. The knockoffs of iPhones are just as good.

The future growth of China is going to be with domestic consumption. Low, skilled labor is leaving and going to other countries.

But, you still have products that I do, products like Apple, and some of these other products as well, that are more complex. They need a sophisticated supply chain.

They need educated engineers because, if you go to these other countries, you’ll have quality problems. It’s not going to be a local engineer. It will be a Chinese engineer that has to get their visa, travel there, then travel back. There’s also going to be communication issues.

There’s just too many problems as of now to say that China is no longer relevant. Maybe another 20 years, but for now, even with the tariffs, China is more competitive than most countries.

So, if we have tariffs from China, why will we not have tariffs in Vietnam, Thailand, and these other countries? Once you give a country like China IP, there’s always going to be some people that rip it off.